ACCUCHROME GC

Galvanic’s Btu and hydrocarbon gas chromatograph, the AccuChrome analyzer is designed and built for critical process-monitoring and control applications in the harshest environments. It is used for performing Btu and constituent analysis of natural gas such as Methane, Ethane, Propane, iso-Butane, n-Butane, iso-Pentane, n-Pentane, Hexanes, Heptanes Plus, Nitrogen, Carbon Dioxide for custody transfer, process optimization during natural gas fractionation. Advantage of this model is that, will not burn out with loss of carrier gas and can withstand corrosive H2S.

SulfurChrome GC

When you need to monitor odorant levels in hydrocarbons, you require high-sensitivity detection and measurement of the individual sulfur components. Some natural gas pipeline custody-transfer applications also require detailed reporting of sulfur and its various components. Galvanic’s SulfurChrome online gas chromatograph makes it easy, enabling simultaneous, real-time measurement of all sulfur compounds down to the 5 ppb level.

Brimstone

Galvanic analyzers are used to optimize sulfur-recovery units that design of the UV-spectrophotometer-based Brimstone analyzer line. The Brimstone is a unique tail & pit gas analyzer that monitors H2S, SO2, CS2 and COS and is capable of direct coupling to the process. Direct coupling provides the Brimstone with the ability to control sulfur vapor removal more efficiently. .

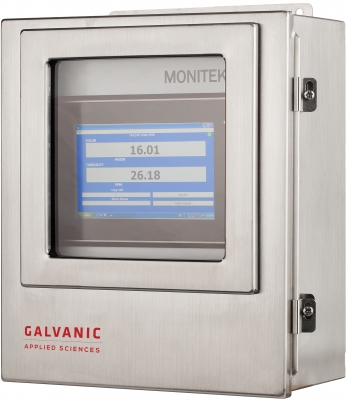

Monitek

Galvanic delivers with its Monitek optical-technology-based turbidity, suspended solids, and color monitors, which delivers the highest performance to cost ratio of any in-line liquid process monitor on the market today. These sensors pair with a messenger controller, which features intuitive multi-language graphical interface, setup via laptop PC or touchscreen, depending on model, automated cleaning cycles, and more. Messenger outputs can interface with customer DCS to provide valuable process information for process control.

Monitek ultrasonic

Sometimes liquids are too opaque or oily to monitor effectively with traditional optical-based technology. That’s where Galvanic’s acoustic-based products come in. Galvanic has a variety of sensor configurations for installation through process pipes, tanks, or open channels to enable real-time measurements and easy insertion and removal without process interruption.

FPA 4100

Galvanic’s FPA 4100 family of process photometers enables measurement of the concentration of a wide variety of analytes in both liquid and gas streams. The photonics module can accommodate either UV or visible light sources and has a temperature controlled photo diode block for maximum signal stability. The FPA 4100 series also enables remote operation and diagnostics via an Ethernet connection.